Print Quality Inspection

Improve the speed and accuracy of your quality process by automatically checking content as it moves through your manufacturing line. Increase your product quality and optimise your production.

Quality Insection Solution

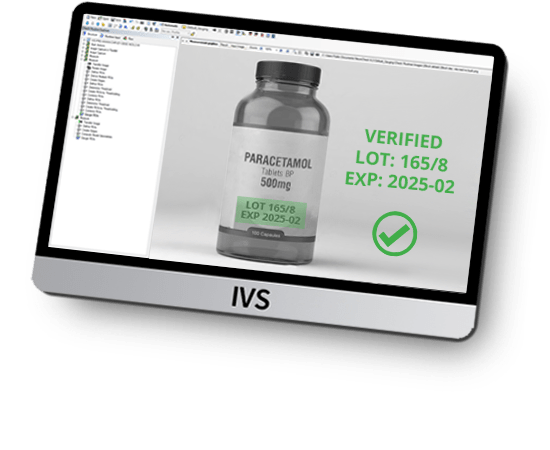

Print Quality Inspection

Instantly catch your critical errors before they even leave your production process. We help companies in regulated industries get to market faster without compromising quality – catching errors as soon as they appear by pinpointing exact differences between the trained files and your current production. Spot print quality errors as soon as they happen, set alarms and stop delivering inferior products to your customer.

Advanced print inspection solutions

Typical Print Quality Inspection (PQI) applications

- Verify print content of pre-printed boxes

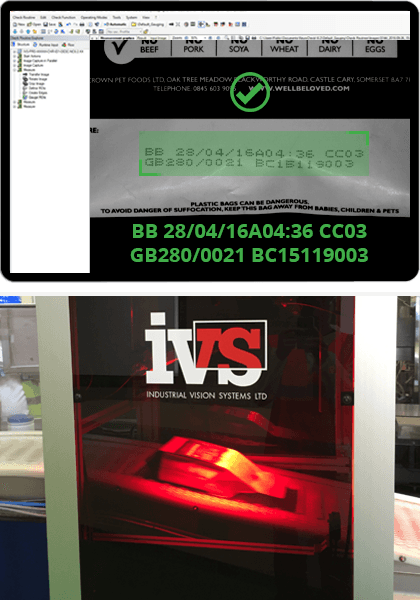

- Check quality of use by dates

- Run side-by-side comparison of digital files

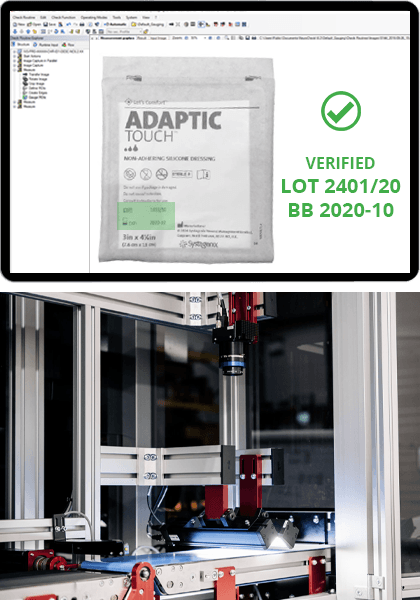

- Check medical device printing

- Reading text and check human-readable errors

- Check ink print is still readable

- Verify alignment, streaks and voids on print

- Detect pin-holes in continuous printing and off-set

- Web surface inspection of printed material

- Direct thermal print inspection

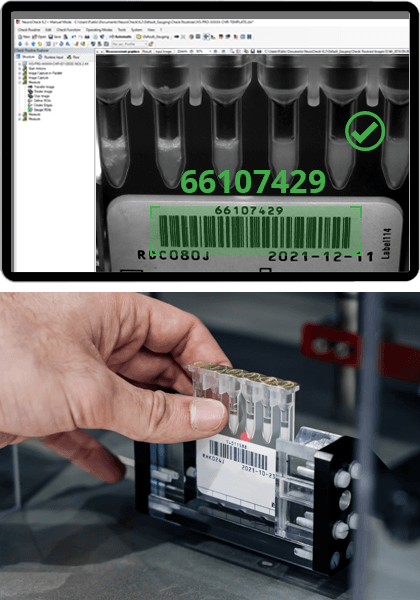

- Verify lot codes, batch numbers and 2d codes

- Identification of special characters

- Verify pharmaceutical traceable text

- Traceability of printed or handwritten text

- Check label print is legible

- Detect changes in ink levels and print registration

Latest Generation Advanced Algorithms

Print Quality Inspection Vision Systems

Machine vision print quality inspection is used to automatically check printed, scribed or stamped text at high speed to confirm text readability, quality and form. More detailed analysis such as missing or touching characters, dimensional checks, skew and distortion can also be analysed. Verify alignment, streaks and voids in print at high speed using automated inspection.

Simple and reliable systems designed by experts

Explore some of the key features and benefits of using an IVS system for Print Quality Inspection

Regulatory control

Ensure products are accurate for internal reviews and regulatory compliance for sale into the market with the correct markings.

Remove the human element

Machine vision eliminates the human error factor and consistently produces accurate results. All products are inspected for 100% accuracy.

Reliable information

Keep track of all print inspected with spreadsheet or SQL data logging for comprehensive production traceability. Drill down on errors.

Print Quality Checks Using Machine Vision

Powerful print inspection algorithms

Artwork and print errors are one of the largest causes of product recall. Our vision systems proof read at speed confirming artwork and print are compared to the master file. Real-time, automated inspection reduces print failures leaving the factory door.

IVS inspection systems allow the user to proof the content of the artwork at speed, at each of the production stages easily and quickly. Allowing our customers to maintain a high reputation, avoid reprints, lower their costs, and reduce time to market.

Powerful algorithms locate text and easily identifies characters that are translated, rotated and scaled to sub-pixel accuracy. IVS® neural network tools can learn to recognise characters, symbols and digits, etc.

Zero Defect Deliveries

Complete print comparator inspection

Automated vision systems for print comparison prevent job mix-up, identify defects in real time, allow the operator to implement corrective actions immediately, reduce material waste, and avoid costly reprints.

Many applications, such as pharmaceutical or high-quality packaging materials, clients require zero defect deliveries. To help print shops perform efficient 100% quality control and deliver defect-free material, IVS has developed a complete range of in-line inspection systems. Whether you produce folding cartons, labels, leaflets or flexible packaging, IVS have the solution that suits your needs.

100% automated print inspection systems monitor the entire print job, check it against the customer proof, and alert the operator in case of random or process print problems.

Increase operator satisfaction

The benefits of print quality inspection

Improve operator satisfaction by simplifying print quality management. Automated vision inspection for print quality allows any operator to complete a meaningful in-line check with ease. Vision systems warn the operator if there are major discrepancies, thanks to its artificial intelligence technology.

As a result, the inspection system helps to reduce eye strain and tiredness. The operator may clearly comprehend the position and origin of printing errors thanks to the clear presentation of deviations and crucial statistical information, such as the defect heatmaps. The comprehensive inspection report, which is generated automatically at the end of each task, provides managers with excellent tracking, analysis and communication support.

More about IVS machine vision Print Quality Inspection applications

The importance of machine vision in producing error-free packaging.

As the complexity of developing, distributing, and selling products grows as a result of globalisation, more firms are turning to automation to help them manage their operations. While automation has traditionally been used in areas such as production, marketing, and even sales, quality control is one aspect of business operations that is increasingly being automated. Because organisations, especially brands, tend to concentrate their technology on product features or consumer benefits, the productivity gains associated with automated quality control are sometimes underestimated. They shouldn’t be, though. Any company whose products end up in the hands of customers should think about the value of good packaging.

Pharmaceuticals, printers, and consumer goods companies face their own set of issues when it comes to guaranteeing packaging quality, with thousands of products and hundreds of SKUs. As anyone working in these fields knows, guaranteeing packaging correctness is no easy chore, especially in this day and age when a single minor mistake can have major ramifications for your business. For example, a misprinted label can cost a business thousands of dollars in tangible items and even more in brand equity when customers lose faith in the brand. Do you believe this will never happen to your company? Reconsider your position. These kinds of mistakes are far more common than one may believe. The bulk of FDA product recalls are caused by labelling errors year after year. Automated quality checks have become the gold standard across a range of industries due to the risk of packing errors combined with more complex rules.

Make your quality control more efficient. Productivity is the key to staying ahead of the competition and growing profits. IVS helps print firms save time by implementing new projects and performing a fast and efficient 100 percent print inspection thanks to its automated work set-up and high inspection speed. The customer proof is automatically imported based on the job data and is used to expedite work setup. Even composite works, such as front and back labels, can be compared to a master product. Exceptional precision allows it to spot errors even at rapid speeds. Jobs are processed and proofed faster as a result.